Calyos is a young company based in Brussels, Belgium that claims to be the global leader in Advanced 2-Phase Cooling Solutions for electronic components. When you consider that Calyos has a mere 28 employees (and that Belgium is hardly renowned as a hotbed of technology) it sounds like a bold claim that that deserves further attention.

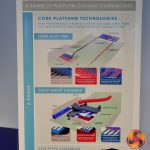

Loop Heat Pipe cooling is a close relation of the heat pipes you find in the cooling systems of most laptops and graphics cards. The heat pipe is a metal tube that is sealed at both ends and contains a small quantity of fluid. One end of the tube contacts the heat sink on, say, a GPU and the other is fixed to a heat exchanger.

The cycle works like this; first the GPU gets hot and transfers heat via the heat sink to one end of the heat pipe. The fluid inside the heat pipe boils and the vapour rises until it contacts the heat exchanger. This cools the fluid which condenses and drips back down the heat pipe until it reaches the hotplate and is vaporised once again.

There are two distinct problems here. Vapour rises and fluids falls, depending on the orientation of the system and the nature of gravity. Secondly, the fact that vapour and fluid are in the same tube makes the process rather inefficient.

The fundamental difference with loop heat pipe cooling is that there are two tubes, one for vapour and the other for condensed fluid. This separates the vapour and fluid which makes the process far more efficient and also means that gravity plays no part in the equation. Furthermore, companies such as Calyos can build systems that do not require a pump and which are entirely passive. You may choose to put fans on the heat exchanger to shift air away from the heat exchanger but the actual loop heat pipe has no moving parts.

Imagine an All In One such as Corsair H100i that is built by Calyos instead of Asetek. Let’s call it the H210. You still have a copper heat sink clamped to your CPU which is connected to the 240mm heat exchanger by two tubes or pipes. The heat exchanger may (or may not) employ two 120mm fans to remove the heat and transfer it to the air around your PC.

The difference is that the system does not require a pump and is therefore quieter and also has one less point of failure. The tiny pumps used in AIO coolers do not have a good reputation.

Calyos tells us the underlying technology was invented in 1971 and we saw a massive cooler that was used beneath French metro trains 40 years ago. Improving the technology to increase efficiency and reliability has taken many years and now Calyos is confident it can be used in rack servers, satellites, military vehicles and regular gaming PCs.

The military application is interesting but no, we weren’t allowed to take photos in that area. Here, however, are the other shots from the day.

(editorial continues after the gallery).

Below a Gallery detailing various shots of inside Calyos

Imagine you have a bunch of electronics inside the tank that requires cooling. You clamp on a heat pipe cooling system that bolts to the side or roof of the tank and use the 60 tonne chassis as a passive heat sink. This works well in Europe but rather less well in the heat of a desert as the sun makes the top of the tank very hot.

Switching to a loop heat pipe system solves the problem as you can simply bolt the cold end to the bottom of the tank where it is protected from the sun. Remember, a loop heat pipe system doesn’t care about the orientation of its installation so ‘down’ works equally as well as ‘up’.

In a similar manner, if you are cooling hardware on a satellite in space you cannot use a heat pipe that relies on gravity, for the obvious reason.

The intriguing thing is that Calyos is using old technology but has developed new processes that allow it to work efficiently. If you take a cross section of the blue Calyos unit you will see how it works but will be unable to replicate the technology.

Here’s what we learned from Nicolas Depret, Head of Engineering at Calyos. The porous material that is attached to the copper heat sink is pure nickel and is sintered to bond it to the copper plate

The sintering process is secret. The 500,000 euro furnace heats the assembly quickly to over 900 degrees C and then hits an exact temperature with a tolerance of 3 degrees. After the cycle is complete the furnace enters cooling mode and ejects the work when it is at around 100 degrees.

Calyos can sinter about 25 units at a time, at a rate of one batch every hour, which makes it easy to estimate their production capacity.

The other secret part of the process is the way that Calyos fills each system and then tests the flow rate before they cut and seal the filling tube.

KitGuru says: In many respects the least interesting fact about Calyos loop heat pipe cooling systems is the point that the heat exchangers can be cooled either actively or passively. Instead you should focus on the absence of a pump and the way the cooling fluid circulates without any mechanical assistance.

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards