CoolChip Technologies, a startup from Massachusetts, promises a breakthrough in computer cooling by reinventing the way modern cooling systems work. While the tech itself seems to be simple enough and may bring in a lot of benefits, it requires major changes in the way how computer coolers are made.

Air-cooling remains the most popular method of cooling chips inside personal computers. The principle of air-cooling is simple: heat is taken off a chip to a heatsink and then the radiator is cooled down using airflow generated by the fan. Air coolers are made by tens of companies, are affordable, efficient, widely available and reliable.

At present, there are several ways to improve performance of computer cooling: by using higher-speed fans, larger heatinks, hybrid cooling systems or unconventional cooling technologies (peltier, phase-change, liquid nitrogen/helium, etc.). All of the aforementioned technologies either cost a lot, produce too much noise, require too lot of space, or are just not reliable or not practical to use.

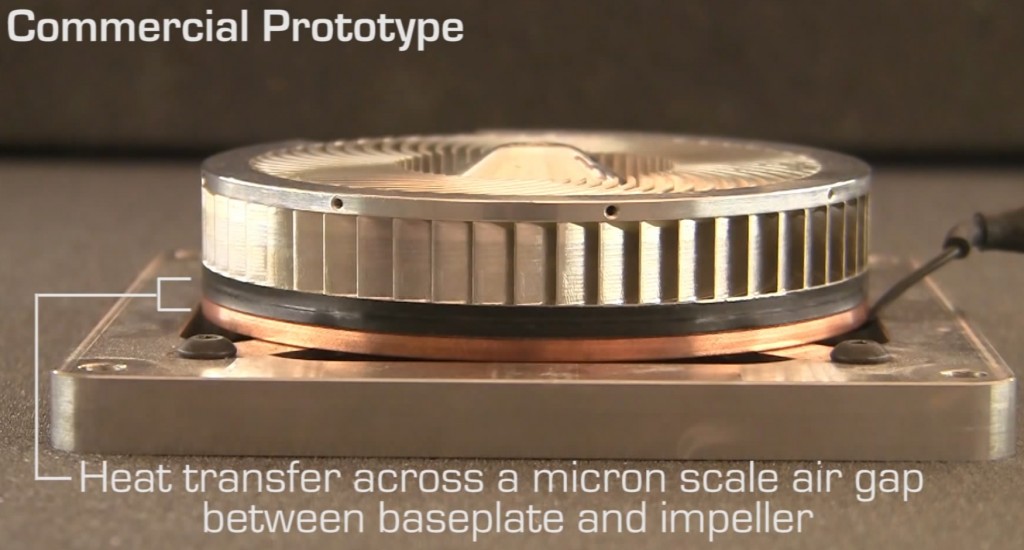

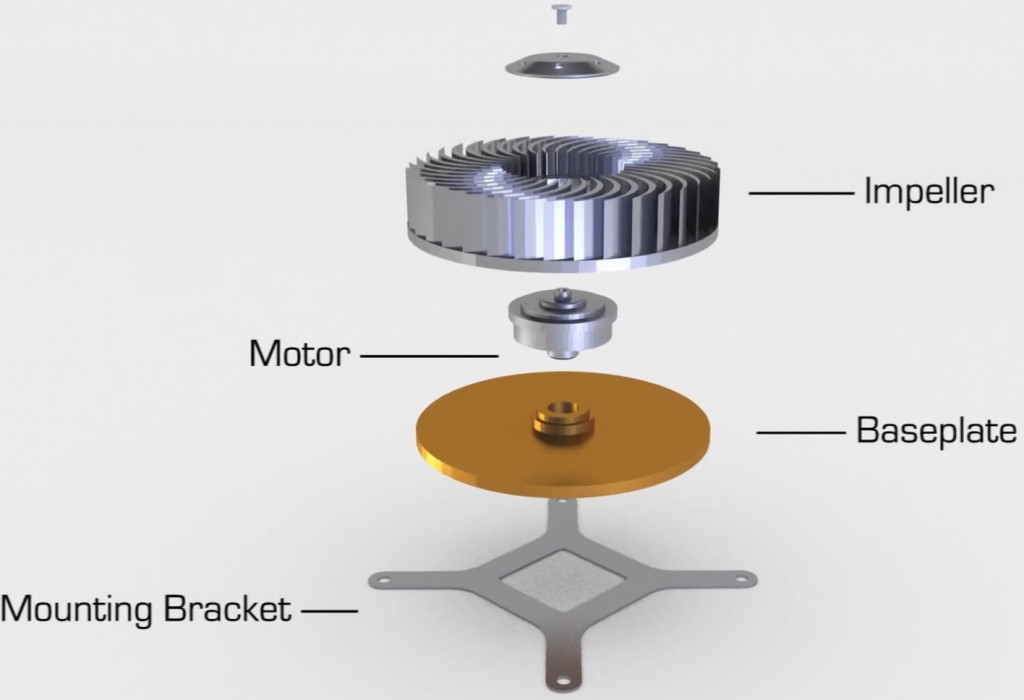

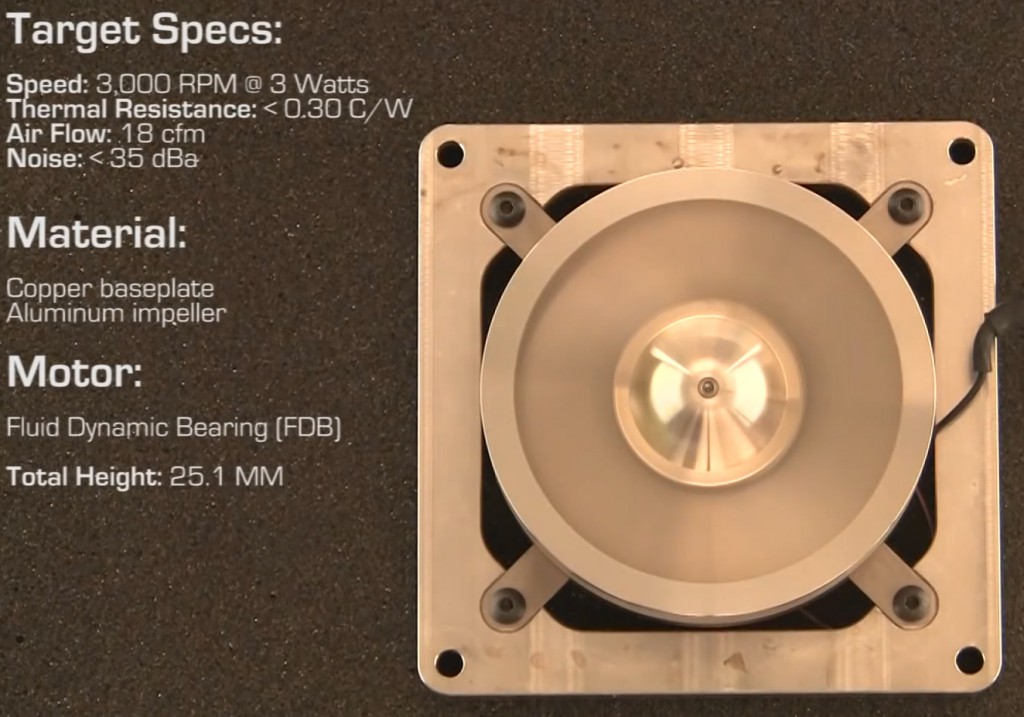

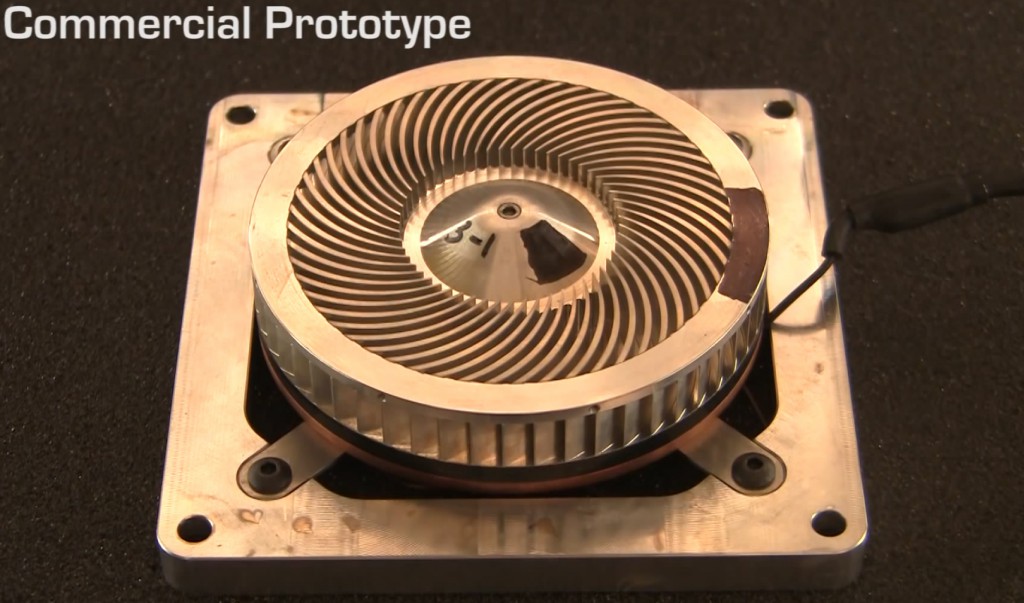

CoolChip Technologies proposes to improve efficiency of air-cooling by using fans as heatsinks. CoolChip calls its approach “kinetic cooling technology” and claims that it is 35 – 40 per cent more efficient compared to conventional coolers. The principle behind kinetic cooling technology (KCT) resembles that of traditional air coolers: the heat from a chip is transferred to a copper baseplate that (unlike usually) does not have fins. Instead, a metallic fan (impeller) is located just several microns above the baseplate and absorbs its heat because of normal convection. Since the fan is rotating, it naturally takes the heat away. Moreover, given that it is easier to cool-down a fan that absorbs heat instead of cooling down a heatsink, the KCT assembly is more efficient than regular coolers.

The assembly of a KCT cooling system requires high-precision mechanics that is akin to assembly of a hard disk drive a couple of decades ago. The flying height – the distance between the disk read/write head on a hard drive and the platter – is just three nanometers today, but many years ago it was several microns. CoolChip wants to use similarly precise technologies for cooling chips down.

The core advantage of contemporary cooling solutions for personal computers is their easy manufacturability and low costs. High-precision mechanics necessary for CoolChip’s cooler assembly is hardly a low cost technology, advanced manufacturing tools are needed to produce KCT-based coolers, so many suppliers of PC cooling systems will not be able to take advantage of the tech. Moreover, it is barely as reliable as today’s coolers because it can be damaged by an impact during installation, handling or usage. In fact, in order to prevent damages caused by coolers themselves because of thermal expansion, special metal alloys will be needed, something that will further increase the costs of coolers powered by the CoolChip’s tech. Finally, the micron-wide gap between the copper basepate and the impeller as well as spaces between fins will inevitably become clogged with dust, dramatically reducing efficiency of the whole solution.

But despite of all the risks and potential disadvantages kinetic cooling technology brings, it theoretically remains a very efficient way of cooling down chips. As a result, Cooler Master and Microsoft Corp. recently got interested in the KCT, reports TechCrunch. Therefore, the tech has potential to actually make it to real products. [yframe url='http://www.youtube.com/watch?v=DWijjwW8Dcc']

Discuss on our Facebook page, HERE.

KitGuru Says: Using a fan as a heatsink seems to be a nice idea in general. However, a micron gap between the fan and the baseplate seems like a very unreliable thing. While it is possible to widen the gap, too much air between the metals means that efficiency will get worse since air is not a good conductor. All-in-all, the time will tell whether kinetic cooling technology makes sense or not.

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards

This will be great for mineral cooled PC’s, Or better yet console’s.

( My main issue I come across with most console’s from 7th gen and 8th is dust issue’s resulting in overheating/burning parts in the motherboard let alone the ram or GPU/CPU. )

I was considering doing that with my Xbox, 360, ps3, but the thermal paste get’s eaten by the oil.

( 8th gen was a total let down, maybe if it came out of the door’s with £300ish price tag would of helpet and I would of waited until this time for it to drop and stick at around £200-250 price point with bundle’s)

I do like my AMD 8350 build and love that I know how to build and overclock aswell as other stuff i’ve picked up along the way, but most people I know have to much of a busy life style and have no time for that earning peanut’s for full time job’s to even have the confidence to work it out.

These console manufactures need to step it up by stepping down on wasting money on fake advertisement and a number of other issue’s most people can easily list out, but something like this in bulk buy and a closed off system would make that 10 year guarantee easy to slap on their product aswell as saving money on repair’s to use on 1440p/1080p Pc’s/console’s.

This is surely a great idea, but they forget something basic. Dust.

Without a proper dust-isolating case, this arctifact is just crap.

Surely if the gap was reduced to mere nanometers dust clogging couldn’t possibly be a problem? I know dust is small but it only gets so small, right?

as long as it remains in the mineral oil the thermal paste loss wont mean a thing. coming from a ncix which had a mineral cooled pc for years. just dont take it out and run it on air without adding more or it will burn up.

I thought Sandia were developing this. 😐

Enclose it in a closed loop, oil-filled system?

Dry Cooker

yeah, that’s right… and if a hard disk head hovering 3nm over a platter crashes when it hits dust instead of just floating over it like it used to (of course causing a read error!)… then surely using a nanometre small gap would stop dust getting in!! plus, the air bearing you get under the impellor and plate would help kick dust off it! hard drives are capable of doing that sort of thing with the help of carbon filters, anyway!!

Eh. Does it really matter who develops it? More competition is good, but I’m not sure if this start up is necessarily a competitor or just a brand to represent the product.

I just saw the vid via techcrunch. Competition maybe good. But it wouldn’t be exactly fair copying others’ work.

Edit: Sry i meant to reply to jake hartman

The air gap doesn’t seem like a good solution. Maybe oil or something would be better for heat transfer?

If you are enclosing the fan in any way then you are trapping the heat and needing to add more cooling fins outside the enclosure. Oil filled system would have the same issue where once the oil does heat up (and it will) there will be no place for the heat to escape. That is why we have oil filled radiators to keep us warm.

Any sort of item with fins will always need to be dusted and cleaned to work best. This wouldn’t be a problem if we all knew how to keep the airflow right in every case but designs are so different from one another that it is not possible.

The key really would be to be able to segment the PC into individual cooling chambers but that would require a complete re-design on the PC platform.

Sandia is broke they have no more government funding.

The micro air gap creates a very unique and interesting heat transfer situation. It exponentially more effective at transferring heat as compared to a thicker layer of air. Because of the sheer speed, it works. You could take a look at their description for more details, it is really cool.

They’ve not forgotten about dust. Read the sandia description. The sheering force created in the air gap stops dust from collecting (inbetween the two pieces of metal).

The fins will collect some dust, but less than a standard heatsink as it spins like a fan. Think of the amount of dust a fan collects on it’s fins, it should be around that amount, if not slightly less.

WOW! It makes a nice music too! Amazing…

BTX was an attempt to that direction. It had a much more rational CPU cooling system than ATX. GPU cooling was also potentially improved with more room for the GPU cooling solution without blocking adjacent slots. Overall BTX would have been a significant improvement over ATX, so it’s sad that it didn’t stick.