Today we take a look at the Hydro G PRO range of power supplies from FSP, new fully modular units with 80 Plus Gold Certification. The Hydro G Pro range is supplied in four capacities – 650W, 750W, 850W and 1000W. FSP told us they are not compromising in regards to the quality of these units, incorporating Fluid Dynamic Bearing fans, a semi fanless cooling mode and 100% Japanese capacitors for long term reliability.

Many major power supply manufacturers are adopting Fluid Dynamic Bearing fans this year, as they keep noise levels down and have a good reputation for lasting the distance. While these units have 80 Plus Gold Certification – in 2019, we consider this entry level for our target audience – the discerning enthusiast.

FSP are a large global OEM and they have made power supplies for many companies over the years including Antec, OCZ, Silverstone, Thermaltake, Nexus and Zalman. The big issue I have with FSP is that they don't seem to sell a lot of their units in the United Kingdom, or even parts of Europe.

Hydro G Pro 850W Overview:

- Compliance with newest ATX12V V2.52

- Efficiency ≧ 90% at typical load

- Intelligent fan speed control

- Quiet and long-lasting 120mm FDB fan

- Ribbon cables design for enthusiasts

- Powerful +12V single rail design

- Full Japanese electrolytic capacitors

- Intel Latest CPU ready

- Full protections: OCP, OVP, SCP, OPP, OTP

- Conformal coatings for harsh environments

The FSP box artwork for the Hydro G PRO series is quite effective. Its very ‘sci-fi' and incorporates clean artwork across the bottom, highlighting the key features and use of Japanese capacitors and modular cables throughout.

Inside the box are some stickers (which you can adhere to the power supply itself to change the colour scheme if you wish), literature on the product, and a big felt bag of modular cables. There was also a power cable in the box – not for UK region (but more on this later).

FSP have included all ribbon style cables in the bag for ease of routing. They are high grade.

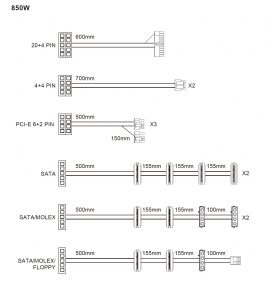

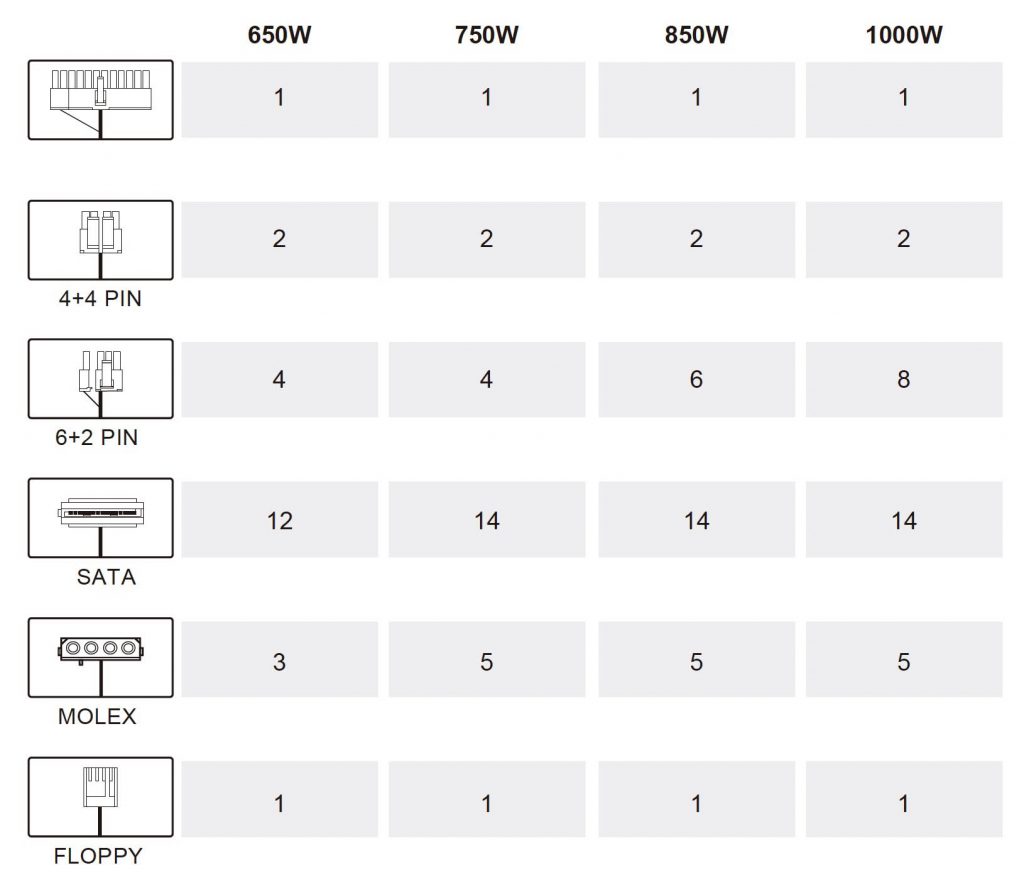

The 850W model we are reviewing today ships with 6 PCIe connectors, 14 SATA connectors, 5 MOLEX connectors and single floppy connector for those of you still using a floppy drive – anyone?

The FSP Hydro G Pro is really nicely finished, and the paintwork is fairly resistant to scratches. The Hydro G Pro logo takes pride of position on one of the side panels – finished in white with a touch of blue on the ‘G' of the logo. There are some stickers in the box which allow you to change the colour to either red or green.

The top of the unit is home to the fan, hidden behind a metal grille, cut in an unusual design.

One side of the power supply is heavily vented to allow for good airflow. There is a power connector, button and ECO on/off switch here. FSP say that when the ECO switch is on, the fan will not operate until the load is over 30%.

The modular bay on the other side of the power supply is neatly laid out and labelled for ease of use during the install phase. I can't say I am a huge fan of the ‘brush script' style ‘PRO' font here , in capitals to boot. The eagled eyed among you will realise that this is not silk screened onto the unit itself, its just a big sticker – which can be peeled off. We actually had to remove it, to get inside the unit.

| FSP Hydro G Pro 850W Power Supply Review | |||||

|

DC Output

|

+3.3V

|

+5V

|

+12V |

-12V

|

+5Vsb

|

|

Max Output

|

20A

|

20A

|

70.83A |

0.3A

|

2.5A

|

| Total Power | 120W | 850W | 3.6W | 12.5W | |

| 850W | |||||

The single +12V rail is able to deliver almost 71 Amps or 850 Watts of the total load.

FSP are using a Protechnic Electric Fluid Dynamic fan to cool the Hydro G 850W supply. Model number MGA12012XF-025 (12V 0.52A). A small plastic flap with some small holes cut into it ensure the air flow hits specific parts of the unit to keep it cool.

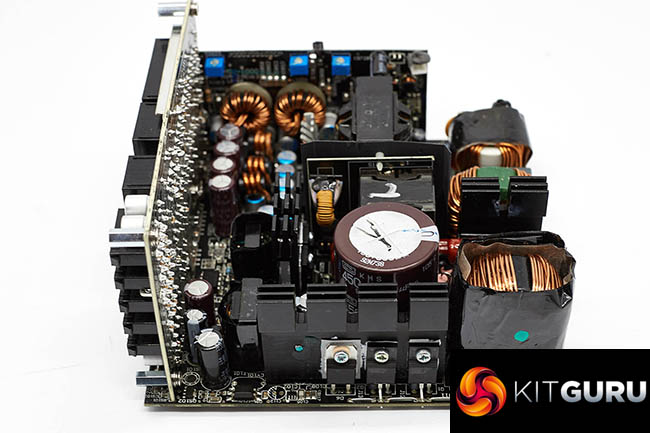

Below - a High Resolution Gallery of the internal layout of the Power supply.

This FSP design incorporates a few small heatsinks across the board and is nicely laid out and the soldering standard is of a high standard. They are using a 3.3V and 5V DC-DC module design to help improve voltage regulation for all rails. We can see there is a new heat sink design for the 12V switching circuitry – which conducts the heat through a thermal pad on the bottom of the PCB – helping to improve cooling.

FSP are using Japanese caps throughout the design which is good to see. The Primary capacitor is 105c rated, by Nippon Chemi Con (KHS series) – rated 450V 680uF. I rate Nippon Chemi Con very highly – I have never seen one fail in the 15+ years I have been doing this.

The Hydro G PRO 850W power supply confirms to OCP, OVP, OPP, SCP and OTP protections and is rated to 100,000 hours MTBF.

Correctly testing power supplies is a complex procedure and KitGuru have configured a test bench which can deliver up to a 2,000 watt DC load. We run at 35c in our environment to greater reflect warmer internal chassis conditions.

We use combinations of the following hardware:

• SunMoon SM-268

• CSI3710A Programmable DC load (+3.3V and +5V outputs)

• CSI3711A Programmable DC load (+12V1, +12V2, +12V3, and +12V4)

• Extech Power Analyzer

• Extech MultiMaster MM570 digital multimeter

• Extech digital sound level meter

• Digital oscilloscope (20M S/s with 12 Bit ADC)

• Variable Autotransformer, 1.4 KVA

We test in a single +12V configuration.

|

DC Output Load Regulation

|

||||||||||

|

Combined DC Load |

+3.3V

|

+5V

|

+12V

|

+5VSB

|

-12V | |||||

|

A

|

V

|

A

|

V

|

A

|

V

|

A

|

V

|

A | V | |

|

85W

|

0.95

|

3.35

|

0.92

|

5.03

|

6.00

|

12.09

|

0.50

|

5.03

|

0.20 | -12.04 |

|

170W

|

1.70

|

3.35

|

1.67

|

5.03

|

12.35

|

12.08

|

1.00

|

5.03

|

0.20 | -12.04 |

|

425W

|

3.00

|

3.34

|

3.05

|

5.02

|

32.20

|

12.06

|

1.50

|

5.02

|

0.30 | -12.03 |

| 640W | 4.05 | 3.34 | 4.05 | 5.02 | 49.00 | 12.04 | 2.00 | 5.02 | 0.30 | -12.03 |

|

850W

|

5.00

|

3.34

|

5.23

|

5.02

|

65.52

|

12.00

|

2.50

|

5.02

|

0.50 | -12.03 |

Load regulation is very strong with the rails holding with 1% of recommended specifications.

| FSP Hydro G PRO 850W Power Supply Review | Maximum Load |

| 923W |

We managed to get the power supply to deliver 923W before it would shut down, delivering around 73W more than rated specifications.

Next we want to try Cross Loading. This basically means loads which are not balanced. If a PC for instance needs 500W on the +12V outputs but something like 30W via the combined 3.3V and +5V outputs then the voltage regulation can fluctuate badly.

| Cross Load Testing | +3.3V | +5V | +12V | -12V | +5VSB | |||||

| A | V | A | V | A | V | A | V | A | V | |

| 760W | 1.0 | 3.35 | 1.0 | 5.03 | 60.0 | 12.01 | 0.2 | -12.03 | 0.50 | 5.03 |

| 165W | 15.0 | 3.34 | 18.0 | 5.02 | 2.0 | 12.08 | 0.2 | -12.04 | 0.50 | 5.02 |

The power supply dealt with the demanding cross load test very well exhibiting little fluctuation. It was tasked with 60A on the +12V rail and it held at 12.01W. The other rails delivered excellent results also.

We then used an oscilloscope to measure AC ripple and noise present on the DC outputs. We set the oscilloscope time base to check for AC ripple at both high and low ends of the spectrum.

ATX12V V2.2 specification for DC output ripple and noise is defined in the ATX 12V power supply design guide.

|

ATX12V Ver 2.2 Noise/Ripple Tolerance

|

|

|

Output

|

Ripple (mV p-p)

|

|

+3.3V

|

50

|

|

+5V

|

50

|

|

+12V1

|

120

|

|

+12V2

|

120

|

|

-12V

|

120

|

|

+5VSB

|

50

|

Obviously when measuring AC noise and ripple on the DC outputs the cleaner (less recorded) means we have a better end result. We measured this AC signal amplitude to see how closely the unit complied with the ATX standard.

| AC Ripple (mV p-p) | ||||

| DC Load | +3.3V | +5V | +12V | 5VSB |

| 100W | 5 | 5 | 15 | 5 |

| 225W | 5 | 10 | 15 | 5 |

| 450W | 10 | 10 | 20 | 10 |

| 675W | 15 | 10 | 25 | 15 |

| 850W | 15 | 10 | 30 | 15 |

Noise suppression is great, peaking at 15mV and 10mV on the +3.3V and +5V rails respectively. The +12V rail peaked at 30mV at full load. Great results all round.

|

Efficiency (%) 240V

|

|

|

100W

|

89.4

|

|

225W

|

91.4

|

|

450W

|

92.0

|

|

675W

|

91.4

|

| 850W | 89.3 |

Efficiency levels are pretty solid for an 80 Plus Gold unit, hitting a peak of 92% at maximum efficiency. This drops to 89.3% at full load.

We take the issue of noise very seriously at KitGuru and this is why we have built a special home brew system as a reference point when we test noise levels of various components. Why do this? Well this means we can eliminate secondary noise pollution in the test room and concentrate on components we are testing. It also brings us slightly closer to industry standards, such as DIN 45635.

Today to test the power supply we have taken it into our acoustics room environment and have set our Digital Sound Level Noise Decibel Meter Style 2 one meter away from the unit. We have no other fans running so we can effectively measure just the noise from the unit itself.

As this can be a little confusing for people, here are various dBa ratings in with real world situations to help describe the various levels.

KitGuru noise guide

10dBA – Normal Breathing/Rustling Leaves

20-25dBA – Whisper

30dBA – High Quality Computer fan

40dBA – A Bubbling Brook, or a Refrigerator

50dBA – Normal Conversation

60dBA – Laughter

70dBA – Vacuum Cleaner or Hairdryer

80dBA – City Traffic or a Garbage Disposal

90dBA – Motorcycle or Lawnmower

100dBA – MP3 Player at maximum output

110dBA – Orchestra

120dBA – Front row rock concert/Jet Engine

130dBA – Threshold of Pain

140dBA – Military Jet takeoff/Gunshot (close range)

160dBA – Instant Perforation of eardrum

|

Noise (dBA)

|

|

|

100W

|

<28.0

|

|

225W

|

<28.0

|

|

450W

|

29.8

|

|

675W

|

32.1

|

| 850W | 34.2 |

Under lighter load situations, the fan does not spin. At around 30% load the fan starts to spin and it becomes audible around 500 watts load – but still very unobtrusive. At higher load levels the fan spins up to compensate for rising heat at at 850Watt, the fan is clearly audible.

It is worth pointing out that you should not really be running an 850 watt power supply at a full 850 Watt load – its putting a lot of strain on the capacitors and efficiency levels are down substantially.

|

Temperature (c)

|

||

|

Intake

|

Exhaust

|

|

|

100W

|

37

|

38

|

|

225W

|

38

|

43

|

|

450W

|

39

|

46

|

|

675W

|

43

|

51

|

|

850W

|

45

|

55

|

The large fan manages to keep things well under control, with the thermal overhead rising to 10c above ambient under full load conditions.

|

Maximum load

|

Efficiency

|

|

923 watts

|

89.2

|

At 923 watts, this unit managed to deliver efficiency at 89.2%.

The FSP Hydro G Pro 850W is without doubt a very fine new power supply release from one of the world's leading OEM manufacturers.

First impressions are positive, I enjoy their sci fi oriented box artwork, and the bundle itself is appealing. I appreciate how FSP include extra coloured stickers for the PSU chassis so you have multiple options to match a themed build.

On a technical level the new Hydro G PRO performs very well, delivering high quality power with tight load regulation. The unit coped well with our cross load testing, and ripple suppression proved very capable indeed with the +12V peaking at 30mV under full load conditions. Minor rails fell well within industry tolerances.

The adoption of a high quality fluid dynamic bearing fan means the power supply never really produces too much noise, and the fan is in fact totally inactive up to around 30 percent load. Under most conditions, the fan spins relatively slowly and it is only once the load hits around 700 watts that the fan spins up to compensate with the rising internal chassis thermals.

My big issue with FSP really is that many of their power supplies are hard to find in Europe, and almost impossible to locate in the United Kingdom. Unless you take a risk and opt for an ebay seller that is. When I asked FSP about the pricing of this particular unit, they said it was not completely confirmed yet, but their ball park figure was $139 in America, when it becomes available for sale.

Considering the low noise levels, quality modular cable implementation, and solid technical performance this unit deserves a worth buying award. If you can find it, you can be assured that your system will be getting quality power for years to come.

The adoption of 105c high grade Japanese capacitors throughout combined with a 10 year warranty mean FSP are standing firmly behind these units. It really is such a shame these new power supplies seem solely focused on the US market. FSP should consider getting a UK distributor involved.

Pros:

- Quality Modular cabling.

- 100% Japanese capacitors throughout from the likes of Nippon Chemi Con.

- good quality of finish.

- technically solid across the board.

- multi coloured stickers for various colour themed builds.

Cons:

- FSP are not targeting the European / UK markets.

KitGuru says: The FSP Hydro G PRO 850W power supply is a solid performing unit that performed very well in all our tests. It is just a shame its not going to be officially available in Europe or UK markets.

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards